- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

2026 Best Slitter Cutter Machine Features and Benefits Explained?

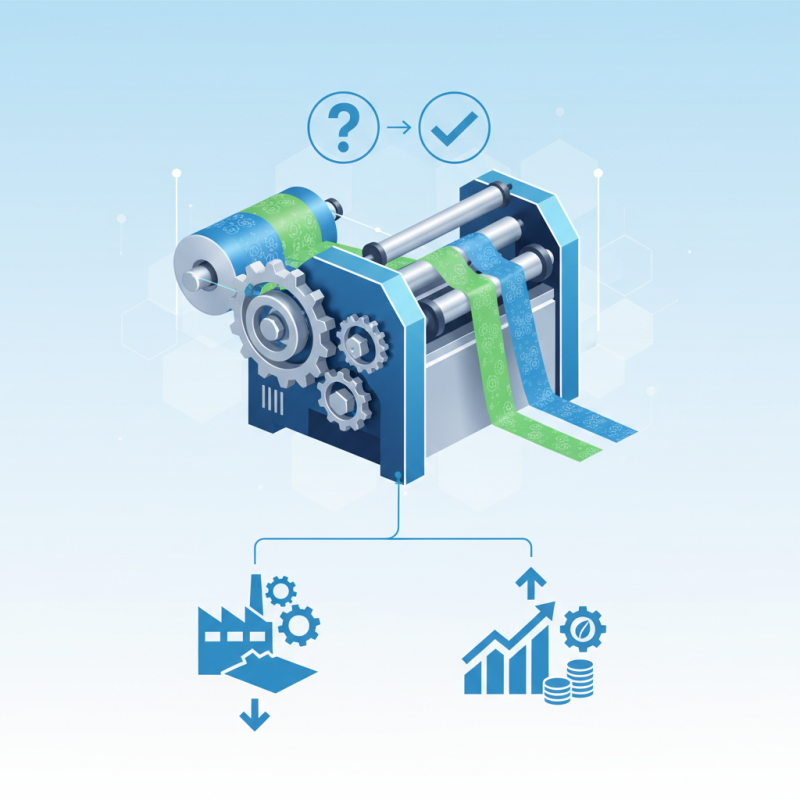

In the rapidly evolving world of manufacturing, the Slitter Cutter Machine stands out for its versatility and precision. As industries adapt to new demands, understanding the features and benefits of these machines becomes essential. Many businesses overlook their importance, which can hinder production efficiency.

The 2026 Slitter Cutter Machine offers advanced capabilities that cater to diverse materials. Its ability to accurately cut various substrates makes it a valuable asset in sectors such as packaging and textiles. This machine is not just about speed; it provides uniformity in cutting, reducing waste and increasing profitability.

Yet, there are factors to consider. Not all models suit every industry. It's crucial to assess production needs before making a choice. Reflecting on the long-term benefits can help businesses make informed decisions. Investing in the right Slitter Cutter Machine may lead to better outcomes. However, it requires thoughtful evaluation.

Overview of Slitter Cutter Machines and Their Applications

Slitter cutter machines play a crucial role in various industries. They are designed to cut large rolls of material into narrower widths. This process is essential for labels, packaging, textiles, and many other applications. The machines can handle different materials, including film, paper, and foil. Their versatility allows manufacturers to meet diverse production needs effectively.

In terms of operation, slitter cutters can be quite complex. Operators must ensure precise measurements for optimal results. Regular maintenance is necessary to keep the machines running smoothly. If not properly cared for, productivity can suffer. Additionally, training staff to use these machines effectively is vital. Misunderstandings during operation can lead to waste and increased costs.

Another important aspect is the machine's efficiency. While some may promise high-speed cutting, real-world results can vary. Real-time adjustments might be necessary to accommodate material variations. Understanding these factors is crucial for businesses. They must think critically about their specific requirements and choose a machine that aligns with them. An informed choice leads to better outcomes in production.

Key Features of the 2026 Best Slitter Cutter Machines

The 2026 best slitter cutter machines bring innovations that are hard to overlook. These machines are designed with precision and efficiency in mind. One key feature is their advanced blade technology. Sharp, durable blades ensure clean cuts for various materials. This results in reduced waste and improved production quality.

Another aspect worth mentioning is the user-friendly interface. Operators find it easy to control settings, which helps reduce errors. Automated adjustments can save time and effort. However, not every user may adapt quickly to these changes. Training is necessary to maximize the benefits of the new systems.

Safety features are also prominent. Emergency stop buttons and safety covers protect operators. Yet, reliance on technology may lead some to overlook manual checks. Regular maintenance is crucial to prevent breakdowns that could halt production. Overall, the 2026 slitter cutter machines are designed for forward-thinking industries, though some challenges still need addressing.

Key Features of the 2026 Best Slitter Cutter Machines

Benefits of Using Advanced Slitter Cutter Technology

Advanced slitter cutter technology offers numerous advantages in manufacturing and production processes. These machines excel in precision, ensuring consistent cuts across various materials. This accuracy reduces waste and improves overall efficiency, which is crucial in today’s competitive landscape. Operators often find that a well-calibrated slitter cutter can significantly speed up production times.

Moreover, using advanced slitter cutters reduces the risk of human error. Automated settings take the guesswork out of cutting, leading to better quality control. This automation can be a game-changer for smaller operations that want to scale up without manual labor strain. However, initial costs can be a concern. It’s essential to evaluate the long-term ROI when upgrading equipment.

Maintaining advanced machinery requires training and vigilance. Operators must be skilled in troubleshooting and routine maintenance. Neglecting these areas can lead to downtime and costly repairs. Constantly reflecting on these processes can help identify improvement areas. Investing in technology is only beneficial if users commit to learning its intricacies.

Comparative Analysis of Different Slitter Cutter Models

When exploring slitter cutter machines, different models offer unique advantages. Some machines are designed for general use, while others specialize in specific materials. For instance, the blade types vary, affecting how efficiently they cut various substrates. High-speed machines might seem appealing, but they require frequent maintenance. Some users find this fact overlooked during purchasing.

Another critical aspect is the machine's size and portability. Compact models can fit into smaller workshops, allowing flexibility. However, these often compromise on cutting volume. Larger versions typically provide higher output but may be cumbersome. It's essential to assess your workspace and production needs carefully before making a decision.

User-friendly interfaces are another feature to consider. Some machines come with advanced controls, reducing the learning curve for operators. Yet, tech-savvy features may lead to glitches. A balance between innovation and reliability is vital. Users sometimes feel overwhelmed by unnecessary features, which complicates operation rather than simplifying it. Ultimately, assessing your specific requirements will guide you in selecting the most suitable slitter cutter machine.

Maintenance and Best Practices for Slitter Cutter Machines

Maintaining slitter cutter machines is essential for consistent performance. Regular inspections help identify wear and tear. Check sharpness of blades often. Dull blades can lead to poor cutting quality. This can affect product output. Cleanliness is crucial too. Dust and debris accumulate and can cause malfunctions. Always keep work areas tidy.

Tips for maintenance:

- Inspect blades weekly.

- Use appropriate cleaning solutions.

- Lubricate components frequently.

It’s important to develop a routine. Over time, operators may overlook minor issues. This can snowball into costly repairs. Training staff on maintenance best practices is vital. They should know how to recognize early signs of trouble. Communication is key; discuss any irregular machine behavior immediately.

Pay attention to machine settings too. Incorrect adjustments can lead to inefficiency. Sometimes, it may be tempting to skip recalibrations to save time. Avoid this; proper settings ensure precision. A well-maintained machine provides not just longevity but also enhances product quality.