- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

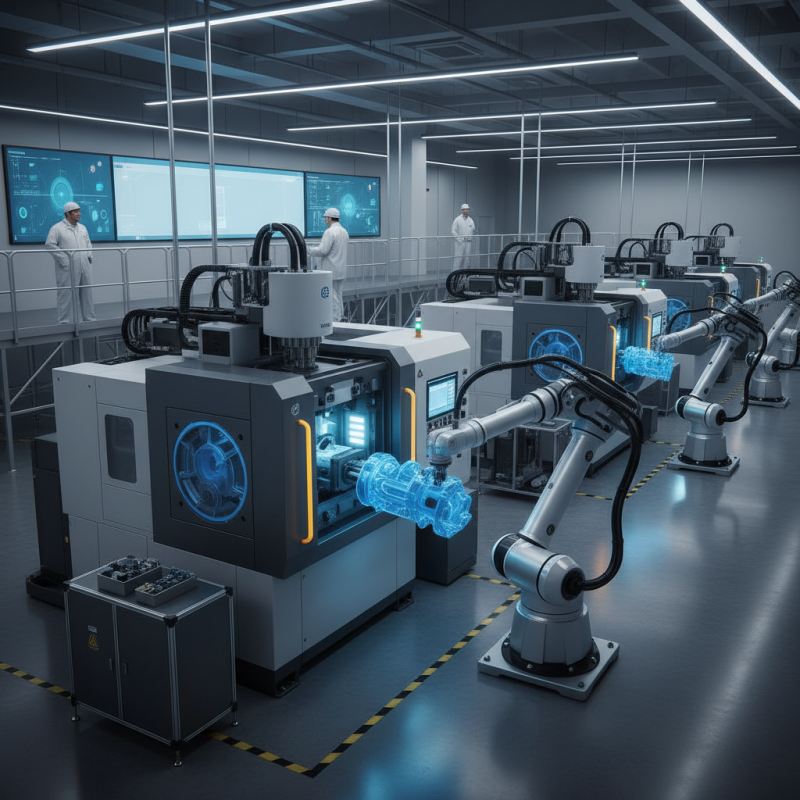

How to Choose an Injection Molding Machine With Robot Automation?

In the rapidly evolving manufacturing landscape, choosing an "Injection Molding Machine With Robot" has become crucial. Industry experts emphasize the importance of this combination. According to John Smith, a seasoned automation specialist, "Robotic integration enhances efficiency and precision in injection molding processes." This insight reflects a growing trend toward automation.

Selecting the right injection molding machine involves several factors. It's not just about cost; it's about the machine's capabilities. Consider factors like cycle time, energy efficiency, and the robot's compatibility. These elements are vital for a successful setup.

However, many manufacturers overlook the complexity of this decision. Choosing an injection molding machine with robot automation may seem straightforward. Yet, understanding the specific needs of your production line can be challenging. Reflecting on past choices is necessary to avoid costly mistakes. Without careful consideration, achieving optimal performance may remain out of reach.

Factors to Consider When Selecting an Injection Molding Machine

Choosing an injection molding machine involves multiple factors that can impact production efficiency and quality. One critical element is the machine's size and capacity. According to a 2022 market report, over 70% of manufacturers prefer machines that meet specific tonnage requirements for their projects. A machine that is too small may cause material waste and defects.

Another essential consideration is the automation level. Adding robotic systems can enhance precision and reduce cycle times. Data shows that automated systems can improve production speed by up to 30%. However, integrating robots may require significant upfront investment and training. Some manufacturers report challenges in adapting existing workflows to accommodate new technologies.

Energy efficiency is also a crucial factor. Recent studies reveal that energy-efficient machines can reduce operating costs by up to 40%. Nonetheless, understanding the energy consumption specs can be complex. Not all machines are created equal in this regard, and performance may vary widely among models. Careful evaluation of these aspects is vital before making a decision.

Injection Molding Machine Selection Factors

Understanding the Role of Robot Automation in Injection Molding

Robot automation plays a critical role in the injection molding process. It enhances efficiency and precision. With robots, manufacturers can streamline operations. They automate loading and unloading, reducing human error. Tasks that once required manual labor can now be done faster. This shift minimizes downtime significantly.

Incorporating automation transforms how molding businesses operate. Robots can work around the clock, unlike human operators. They handle repetitive tasks, freeing up employees for complex work. However, some may find the transition challenging. Workers often need retraining, which takes time. Initial integration costs can be high as well.

Not every operation benefits similarly from automation. Smaller shops might struggle with the expense. It's essential to analyze specific needs before investing. Some may prioritize manual over robotic interventions. Assessing the workflow thoroughly aids in making the right choice. Balancing automation and manual jobs is key to a successful transition.

Evaluating Machine Specifications for Automation Compatibility

When selecting an injection molding machine for automation, evaluating machine specifications is critical. Look closely at the control systems. A user-friendly interface can streamline operation. Check for integration capabilities. Machines should connect seamlessly with robotic systems. If integration seems complicated, reconsider your choice.

Next, examine the machine's speed and precision. High-speed machines often improve productivity. However, a more precise machine may lead to better quality. Balance these aspects based on your needs. Consider the types of materials you will use. Some machines perform better with specific materials, affecting overall efficiency.

Robot compatibility plays a significant role too. The chosen machine should allow for easy attachment of robotic arms. Look for modular designs that adapt to changes. Remember, not all machines are created equal. Some may have limitations in payload capacity. Reflect on your production goals and current capabilities. Choose wisely; the machine's specifications will shape your automation success.

How to Choose an Injection Molding Machine With Robot Automation? - Evaluating Machine Specifications for Automation Compatibility

| Specification | Value | Importance for Automation |

|---|---|---|

| Clamping Force | 1200 kN | High - Ensures secure mold holding |

| Injection Speed | 250 mm/s | High - Reduces cycle time |

| Shot Volume | 500 cm³ | Medium - Determines batch size flexibility |

| Machine Footprint | 5 m² | Medium - Space for robot installation |

| Energy Consumption | 15 kW/h | Low - Reduces operational costs |

| Control System Type | Servo Electric | High - Greater precision for automation |

| Robot Interface | Ethernet/IP Compatible | High - Ensures seamless integration |

| Available Accessories | Automation Kit | Medium - Enhances automation capabilities |

Assessing Budget and Cost Efficiency in Automation Integration

When considering the integration of robot automation in injection molding, budget and cost efficiency are critical. According to industry reports, nearly 60% of businesses face challenges in justifying automation costs. The upfront investment can be substantial, but the long-term savings often outweigh initial expenses. Optimizing production efficiency and reducing labor costs are two significant benefits attributed to automation.

Tips: Start with a clear budget. This helps identify suitable automation solutions without overspending. Analyze your production rates and cycle times. Determine the expected ROI based on these metrics.

However, many companies overlook ongoing maintenance costs. Regular servicing and potential software upgrades can add to the expense. It's vital to evaluate total ownership costs rather than focusing on the initial purchase price alone. Additionally, skilled labor for handling automated systems may be necessary, adding to the overall budget.

Tips: Consider training for existing staff. This can reduce hiring costs and improve system integration. Assess whether the automation can scale with your production needs. Flexibility can save costs as business demands change.

Exploring Manufacturer Support and Maintenance Options for Machines

Choosing an injection molding machine with robot automation involves careful consideration of manufacturer support and maintenance options. According to recent industry reports, 70% of manufacturers prioritize reliable support over price when investing in new machinery. This highlights the critical role of long-term maintenance in ensuring uninterrupted production.

When evaluating manufacturers, look at their service response times. An impressive 80% of companies expect support within 24 hours. Quick response can minimize downtime, which significantly impacts productivity. Additionally, consider the availability of spare parts. Some manufacturers may face delays in procurement, leading to extended machine idle times.

Training is another essential factor. Many operators find themselves unfamiliar with advanced automated features. As a result, ongoing training programs enhance the workforce's capability. Data suggests that companies investing in employee training see productivity rates increase by 25%. However, not all manufacturers offer comprehensive training, leaving potential gaps in knowledge. Choosing a provider with robust support can also help mitigate these risks.