- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

Why Do You Need a Position Sensor in Your Projects?

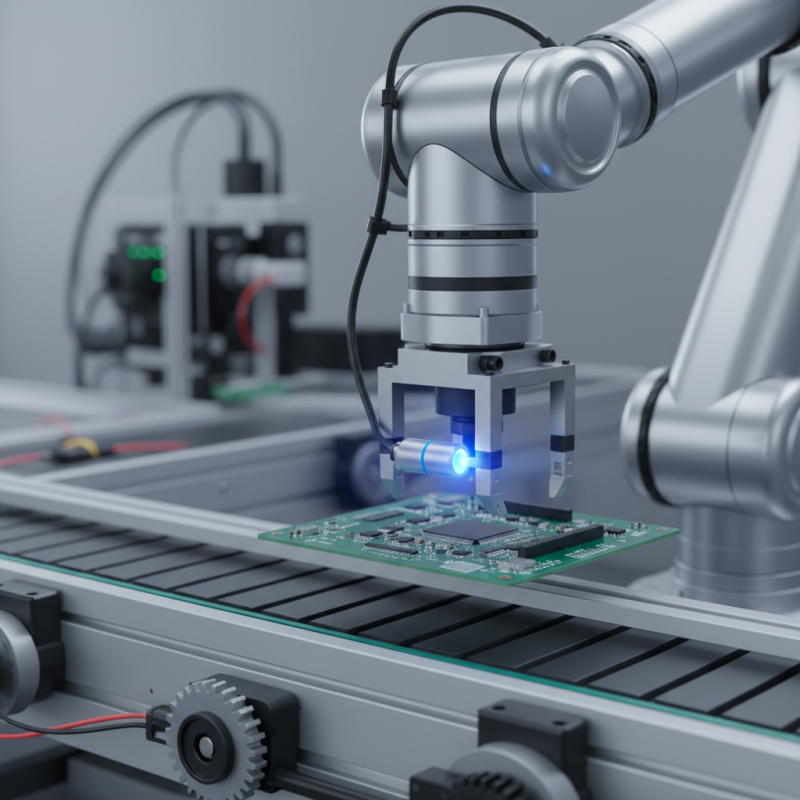

In the world of automation and robotics, a Position Sensor plays a pivotal role. This device detects the location of an object, providing critical data for various applications. Imagine a robotic arm gracefully picking up an object. Without a position sensor, the arm would struggle to know where to reach. This technology bridges the gap between physical motion and digital logic.

Position sensors come in various forms, including encoders and potentiometers. They help in making real-time decisions that can optimize tasks. For instance, in an automated assembly line, the precision of a position sensor can significantly enhance production efficiency. However, some projects overlook their importance, leading to inefficiencies and failed outcomes.

While the utility of position sensors is clear, selecting the right one can be challenging. Not all sensors are suited for every application. This requires careful thought, and sometimes trial and error. As you embark on your next project, consider how a position sensor can elevate your design. Its significance cannot be overstated, and a well-chosen sensor may be the key to unlocking success.

Importance of Position Sensors in Automation and Robotics

Position sensors play a crucial role in automation and robotics. They provide precise feedback on the location and movement of components. According to industry reports, about 70% of automation projects rely on these sensors to optimize performance. Without them, machines would lack the necessary data to function effectively.

In robotics, position sensors help ensure accurate navigation. A robotic arm, for example, needs exact positional information to perform tasks like assembly or welding. Studies show that errors in positioning can lead to a 30% decrease in efficiency. This highlights the essential role that position sensors have in maintaining precision and productivity in automated systems.

However, the implementation of position sensors isn't without challenges. Calibration can be complex and time-consuming. Engineers often struggle with integrating multiple types of sensors. It's vital to assess their compatibility with existing systems. As technology evolves, the demand for more accurate and reliable sensors continues to rise. Creating a balance between cost and functionality is a constant consideration in project planning.

Importance of Position Sensors in Automation and Robotics

Types of Position Sensors: Potentiometers, Encoders, and More

Position sensors play a crucial role in various applications, enabling precise measurements of an object's position. Among the most common types of position sensors are potentiometers and encoders. Each type has distinct functionalities and uses in engineering and robotics.

Potentiometers are straightforward devices. They adjust resistance based on the position of a slider. This simplicity offers ease of integration in many projects. According to industry reports, the global potentiometer market is expected to reach approximately $4.5 billion by 2025. However, they can suffer from wear and tear over time, leading to inaccurate readings.

In contrast, encoders, particularly rotary encoders, provide high precision. They convert motion into an electrical signal. Their use is expanding, with projections indicating a market growth rate of over 7% annually through the next five years.

Other types of position sensors, such as capacitive and inductive sensors, also exist. Capacitive sensors detect changes in capacitance to measure distance. They are often used in industrial automation. However, they may struggle in environments with moisture or dirt. Inductive sensors, similar in function, face limitations in their range but excel in metal detection applications. The choice of position sensor depends heavily on specific project requirements and conditions. Their reliability, cost, and environment suitability should always be evaluated.

Market Trends: Growth in the Position Sensor Industry

The position sensor industry is witnessing significant growth. This trend stems from various sectors, including industrial automation and automotive applications. As manufacturers aim for improved efficiency, position sensors play a crucial role. They enhance precision in tracking motion and positioning components accurately.

Tips: When integrating position sensors, consider the environment. Harsh settings may require specialized sensors. Always account for factors like temperature and humidity.

The market demand drives innovation in sensor technology. Customers seek sensors that are more reliable and cost-effective. Developers must grapple with the challenge of balancing these needs with performance demands. Choosing the right sensor isn't always straightforward.

Tips: Conduct thorough research before selection. Look for user reviews and performance metrics. Understanding your project's unique requirements can prevent headaches down the line.

Why Do You Need a Position Sensor in Your Projects? - Market Trends: Growth in the Position Sensor Industry

| Application Area | Market Share (%) | Growth Rate (CAGR %) | Key Features |

|---|---|---|---|

| Automotive | 25 | 8.0 | High precision, real-time feedback, compact size |

| Industrial Automation | 30 | 7.5 | Durable, reliable under harsh conditions, energy-efficient |

| Consumer Electronics | 22 | 9.0 | Compact, cost-effective, easy integration |

| Aerospace and Defense | 15 | 6.5 | High reliability, precision, and compliance with standards |

| Healthcare | 8 | 10.2 | Compact size, accurate measuring, user-friendly design |

Applications of Position Sensors Across Various Sectors

Position sensors play a vital role in various sectors. These sensors detect the position of an object, providing crucial data for automation and control systems. For instance, in the automotive industry, position sensors help in monitoring the position of critical components like throttle and brake systems. According to a report by ResearchAndMarkets, the automotive sensor market is projected to reach $40 billion by 2025. This reflects the growing need for precise positioning to enhance vehicle safety.

In manufacturing, position sensors are indispensable for robotic applications. They ensure that robots operate with accuracy and efficiency. The global robotics market is expected to grow significantly, reaching over $120 billion by 2025. Position sensors enable robots to perform complex tasks. However, implementing advanced sensors isn't always straightforward. Calibration errors may lead to malfunctions, resulting in production delays.

Healthcare also benefits from position sensors. They are used in medical devices for patient monitoring and surgical robots. The medical devices market is projected to exceed $500 billion in the coming years. Yet, the integration of position sensors in this sector faces challenges. There are concerns about data accuracy and device interoperability. The need for improved sensor technology continues to evolve across industries.

Impact of Position Sensors on Precision and Efficiency in Engineering

Position sensors play a crucial role in enhancing precision and efficiency in engineering projects. They provide accurate measurements of position, helping engineers to create systems that operate seamlessly. According to a recent report by the International Society of Automation, effective position sensing can improve system efficiency by up to 40%. This significant boost can lead to reduced operational costs and increased productivity.

In many applications, the accuracy of position sensors directly impacts the final output. For example, in robotics, a 1mm error can result in a malfunction during operation. This illustrates the importance of precise measurements. Companies often overlook the potential pitfalls of using low-quality sensors.

A report from the National Institute of Standards and Technology highlighted that precision errors can add up, leading to costly redesigns later.

Moreover, as industries push for automation, understanding sensor capabilities becomes vital. Ignoring the need for robust position sensing can limit operational efficiency. Many projects fail due to inadequate specifications on sensor requirements. Engineers must continually reassess their sensor choices to ensure optimal performance in their designs. This reflection can lead to innovative solutions that drive progress in engineering fields.