- Home

- >

- Knowledge Center

- >

- Blogs

Blogs

Sharing knowledge is key to an innovative and healthy industry! This knowledge center is therefore a central place on our website to share information. Read all about our industry in the blogs below!

What is an Isotainer Tank and How Does it Work?

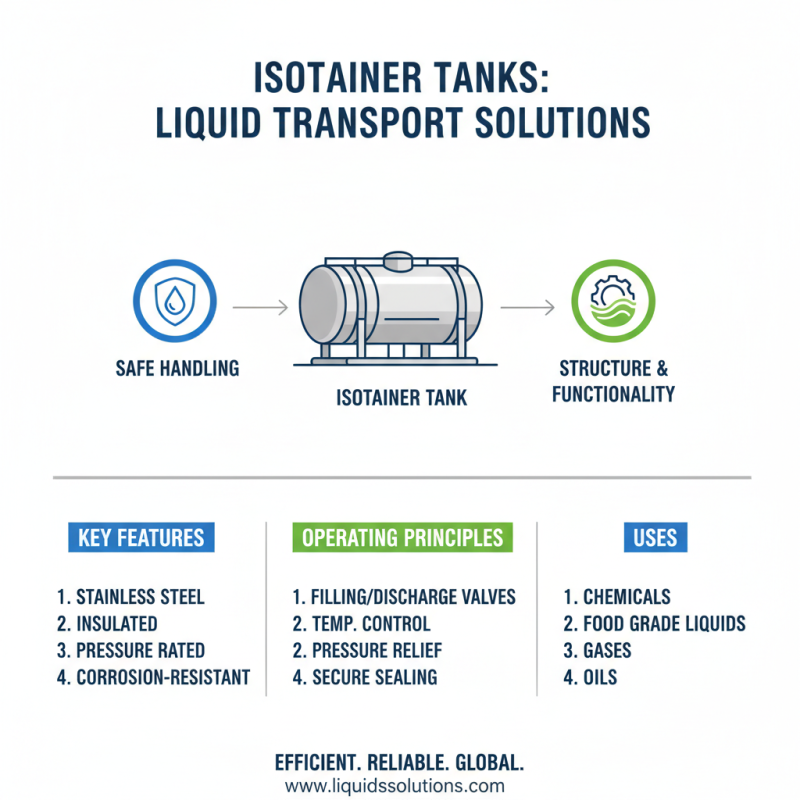

In the world of logistics, the Isotainer Tank stands out as a vital component for transporting various liquid substances. According to Dr. Emily Vargas, a recognized expert in the field, "Isotainer Tanks revolutionize shipping by ensuring safety and efficiency." These tanks are designed to handle a range of liquids, from chemicals to food products, while maintaining optimal conditions throughout the journey.

The design of an Isotainer Tank is not merely practical; it combines advanced engineering with strict safety protocols. Each tank undergoes rigorous testing to withstand the harshest conditions. However, the industry faces challenges, such as ensuring the utmost cleanliness and managing the risk of contamination. The stakes are high, as any oversight can lead to significant consequences.

Equipped with insulation and specialized fittings, an Isotainer Tank streamlines the transportation process. Yet, the complexity of maintaining quality standards can be daunting. The balance between innovation and risk management is fragile. In this evolving field, continuous improvement is essential for success. Understanding the intricacies of Isotainer Tanks requires a commitment to detail and a willingness to adapt.

Definition and Overview of Isotainer Tanks

Isotainer tanks are specialized containers designed for transporting liquids, particularly hazardous materials. They are known for their robust construction and ability to withstand harsh conditions. These tanks are built with safety features that minimize spillage and leaks, ensuring the safety of both the product and the environment.

One important aspect to consider when using isotainer tanks is their capacity. They come in various sizes, allowing for flexible shipping options. However, choosing the right size is crucial. An undersized tank may lead to overloading, while an oversized tank can cause unnecessary costs. Always assess your needs carefully.

Tips: Regular inspections are essential. Check for any signs of wear or damage. A small issue can escalate quickly. Additionally, ensure that the tank is properly cleaned after each use. Residual material can lead to contamination or chemical reactions. Don’t overlook maintenance; it’s key for safety and efficiency in transport.

Components and Construction of Isotainer Tanks

Isotainer tanks are engineered for transporting liquids and gases efficiently. The components of an Isotainer tank include a robust outer shell, insulation, and a secure inner tank. These elements work together to maintain the integrity of the cargo. Many manufacturers use high-grade stainless steel for the inner tank, which ensures durability and resistance to corrosion. Insulation is crucial, especially for temperature-sensitive materials.

According to a 2021 industry report, the global market for isotainer tanks is expected to grow by 4.5% annually. The report highlights increasing demand in the chemical and food industries. The tank’s design minimizes the risk of leaks and spills. Proper construction methods are necessary to avoid potential safety hazards.

However, some construction methods may lead to inefficiencies. Poor insulation can cause thermal losses. It is essential to regularly inspect tanks for wear and damage. Neglecting maintenance can result in costly mishaps. Industry experts stress the importance of adhering to safety standards during production. They argue that better training for personnel could diminish these risks substantially.

How Isotainer Tanks Work: The Operating Principles

Isotainer tanks are specialized containers designed for transporting liquids. They ensure safe handling of various substances. The operating principles of isotainer tanks center around their structure and functionality.

The tanks consist of a sturdy outer shell made from durable materials. Inside, they hold a lining designed to protect the contents. This dual-layer system prevents leaks and minimizes contamination risks. When transporting hazardous materials, the sealing mechanism plays a crucial role. A secure closure is essential to maintain safety during transit.

Tips: Always check for any visible damages before use. Regular maintenance extends the lifespan of isotainers. Training workers on the proper handling techniques is a must.

Inside the tank, temperature controls often exist. These features help maintain the ideal conditions for the contents. It's important to monitor the temperature carefully. Any negligence could affect the quality of the transported liquids.

Accurate labeling is crucial for isotainers. Clear labels reduce confusion during shipping and handling. A small mistake can lead to significant consequences. Everyone involved should understand the labels thoroughly.

Tips: Educate your team about the importance of proper labeling. Inconsistencies can lead to mishaps. Always verify your labels before sealing the tank.

Applications and Benefits of Using Isotainer Tanks

Isotainer tanks are increasingly popular in various industries, particularly for transporting bulk liquids safely. Their flexible design allows for storage and transportation in different environments, from chemical plants to food and beverage facilities. The market for isotainers is expected to grow, driven by the rising demand for efficient logistics. According to industry reports, the global isotainer market is projected to reach $1.5 billion by 2025, reflecting a compound annual growth rate of around 6%.

Using isotainer tanks offers significant benefits. They are made from durable materials, ensuring resistance to corrosion and temperature fluctuations. This durability is essential for transporting chemicals or sensitive liquids. Moreover, a recent survey highlighted that over 70% of manufacturers reported reduced leakage incidents after switching to isotainers. This reduction in spills not only saves costs but also contributes to better environmental practices.

Challenges do exist with isotainer usage. Proper training for handlers is crucial. Mismanagement can lead to contamination or accidents. Additionally, the cost of initial investment might discourage small businesses. These factors merit consideration when integrating isotainers into logistics operations. Industry data suggests that companies embracing these tanks often see long-term efficiency gains, even amid short-term hurdles.

Applications and Benefits of Using Isotainer Tanks

Safety Measures and Regulations for Isotainer Tanks

Isotainer tanks are essential for transporting hazardous liquids, ensuring safe handling and storage. Industry reports highlight that approximately 12% of global shipping involves hazardous materials. Proper safety measures are crucial in this sector. Regular inspections verify the integrity of the isotainers. Reports show that about 30% of isotainers fail safety checks due to wear and tear.

Regulations also play a vital role. Compliance with international standards, such as the IMDG Code, is mandatory. Training for personnel handling isotainers is essential. A survey indicated that 25% of accidents are linked to human error. This highlights the need for ongoing education. Additionally, these measures help reduce the risk of spills and leaks.

Despite progress, challenges remain. Some isotainers have outdated technology that cannot detect leaks early. Investment in modern, high-tech safety systems is needed. Moreover, emergency response plans are not always in place. These gaps leave room for improvement in the industry. Addressing these issues can significantly enhance safety and efficiency in isotainer tank operations.

Related Posts

-

China's Premier Factory Delivering Exceptional Isotainer Tanks for Global Buyers

-

Exploring Business Opportunities: Insights from the 137th Canton Fair on Container Parts Catalog Trends

-

Innovative Solutions for Efficient Iso Tank Transport Logistics

-

Why Is Iso Tank Transport Essential for Safe and Efficient Shipping?

-

How to Choose the Best Iso Tank Fittings for Your Industrial Needs

-

The Future of Eco Friendly Tank Shipping Container Solutions